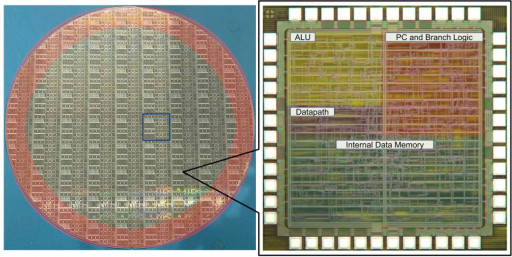

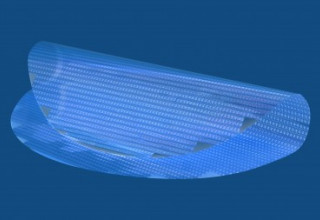

A team of researchers from The Grainger College of Engineering at the University of Illinois Urbana-Champaign, in collaboration with flexible electronics manufacturer PragmatIC Semiconductor, has developed the first commercially viable flexible plastic microprocessor chips, called FlexiCores, that can help everyday objects - from bandages, packages and bottles - become "smart" and manufactured at scale for less than a penny per unit.

"You could put processors on bandages to detect whether a wound is healing or add them to consumer goods packaging to track progress along the supply chain," said Rakesh Kumar, a professor of electrical and computer engineering and researcher in the Coordinated Science Lab at UIUC. "The challenge has been creating a processor that can be both cheaply produced and flexible enough to fit snugly even against uneven surfaces on our body, packages or beer bottles."

To solve the problem, the team turned to plastic, instead of silicon, as the basis of the chips. FlexiCores are built on thin-film transistors made with the semiconductor indium gallium zinc oxide (IGZO), which works even when bent and is compatible with plastic.

"These chips combine the flexibility and cost benefits of plastic technology with the high yield and low bill of materials enabled by our architecture," Kumar said.

With this research, Kumar and his team are pioneering flexible electronics with new application frontiers. The research will be presented at the International Symposium on Computer Architecture later this month.

Media Contact: Chelsea Hamilton, Associate Director of Communications, The Grainger College of Engineering | clhamil@illinois.edu | 217-333-1474

Related Images

Press Release Service by Newswire.com

Original Source: University of Illinois Researchers Create First High-Yield Plastic Microprocessors That Cost Under a Penny Each